With the advancement of time, mechanical equipment such as excavators has become a common sight in our lives. The most prominent feature of an excavator is its bucket teeth, which resemble an elephant's trunk in appearance and serve a similar function. Consequently, they experience significant wear and tear. So, how can we reduce the wear and tear on Ningbo bucket teeth?

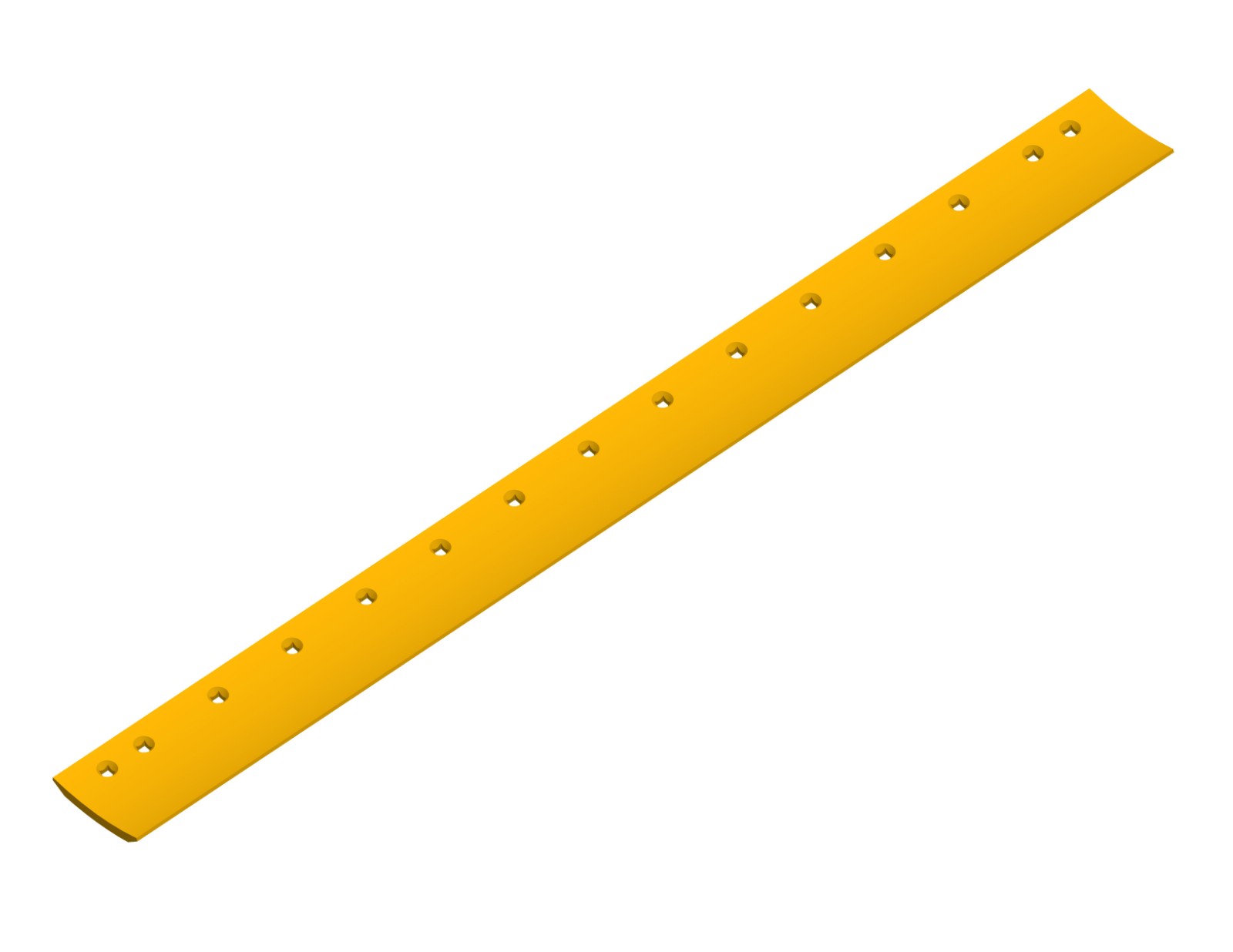

Forged excavator bucket teeth have a wide range of applications, primarily in machines like excavators. There are not many casting methods for bucket teeth, with sand casting and precision casting being the two main methods. Forged bucket teeth are costly and produced in small quantities.

During operation, excavator bucket teeth may sustain varying degrees of damage, leading to failure. Force analysis reveals that the working surface of the bucket teeth comes into contact with the material being excavated. Throughout a complete excavation process, the force distribution varies at different stages. When the tip of the teeth first contacts the material surface, due to the high speed, the tip of the bucket teeth experiences intense impact. If the yield strength of the bucket teeth is low, plastic deformation may occur at the tip. As the excavation depth increases, the force distribution on the bucket teeth changes. When the bucket teeth cut through the material, relative movement occurs between the teeth and the material, generating significant normal compressive forces on the surface, which in turn results in substantial friction between the working surface of the bucket teeth and the material.

Therefore, it is recommended to perform appropriate normalizing treatment on Ningbo bucket teeth castings after casting to improve their structure and properties, thereby enhancing their service life. With reasonable heat treatment of the castings, under the same working conditions, the service life of Ningbo bucket teeth has been nearly doubled.

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province