As the utilization rate of excavators continues to increase, more and more projects are gradually adapting to the presence of these equipment. However, with the use of excavators, the wear and tear on excavator bucket teeth are also intensifying. So, how should we operate excavators in daily use to make more effective use of the bucket teeth?

The importance of diamond-tipped excavator bucket teeth is self-evident, so extra care should be taken when using them, and correct measures must be taken to ensure normal operation of the excavator. So, how should we correctly use excavator bucket teeth? Let me introduce it to you below.

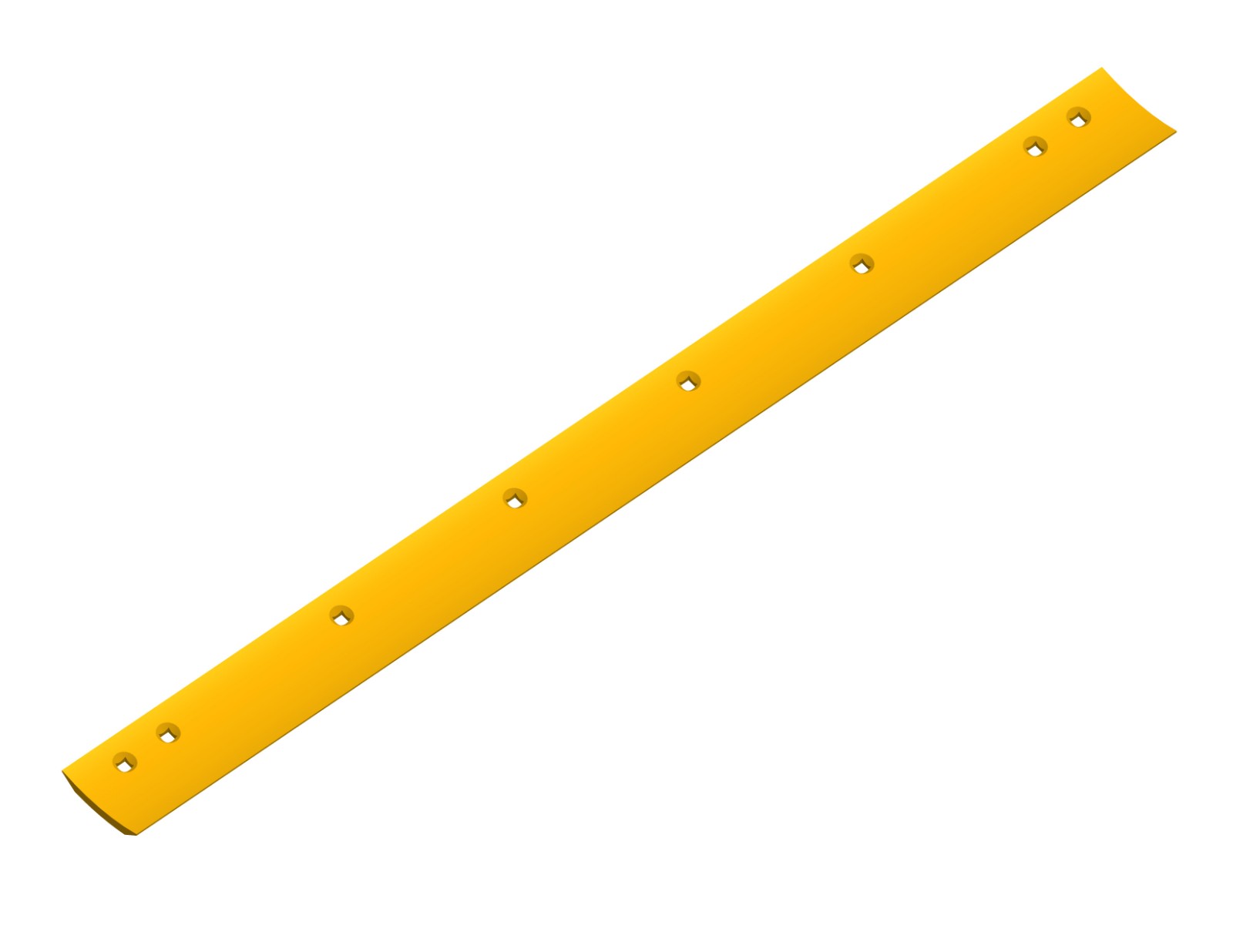

Correct Selection of Ningbo Diamond Bucket Teeth: The first step in using excavator bucket teeth is to make the right choice. The determination of material should be based on the environment, as only this can better ensure the correctness of the choice. Correctly chosen bucket teeth can also perform optimally during use.

Attention to Angle: Excavator operators should pay attention to the operating angle during excavation. Try to maintain a vertical position to the working surface or an outward inclination angle not exceeding 120 degrees when digging down to avoid breaking the bucket teeth due to excessive inclination. Also, avoid swinging the excavation arm left and right under significant resistance, as this can cause the bucket teeth and tooth seats to break due to excessive force in both directions. The mechanical design principle of most bucket teeth models does not account for force applied from the left or right.

Timely Replacement: The wear condition of the tooth seat is also crucial to the service life of the excavator bucket teeth. It is recommended to replace the tooth seat after it has worn by 10% to 15%. Excessive wear between the tooth seat and bucket teeth creates a larger gap, changing the fit and force application point between them, leading to the breaking of the bucket teeth due to altered force application.

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province