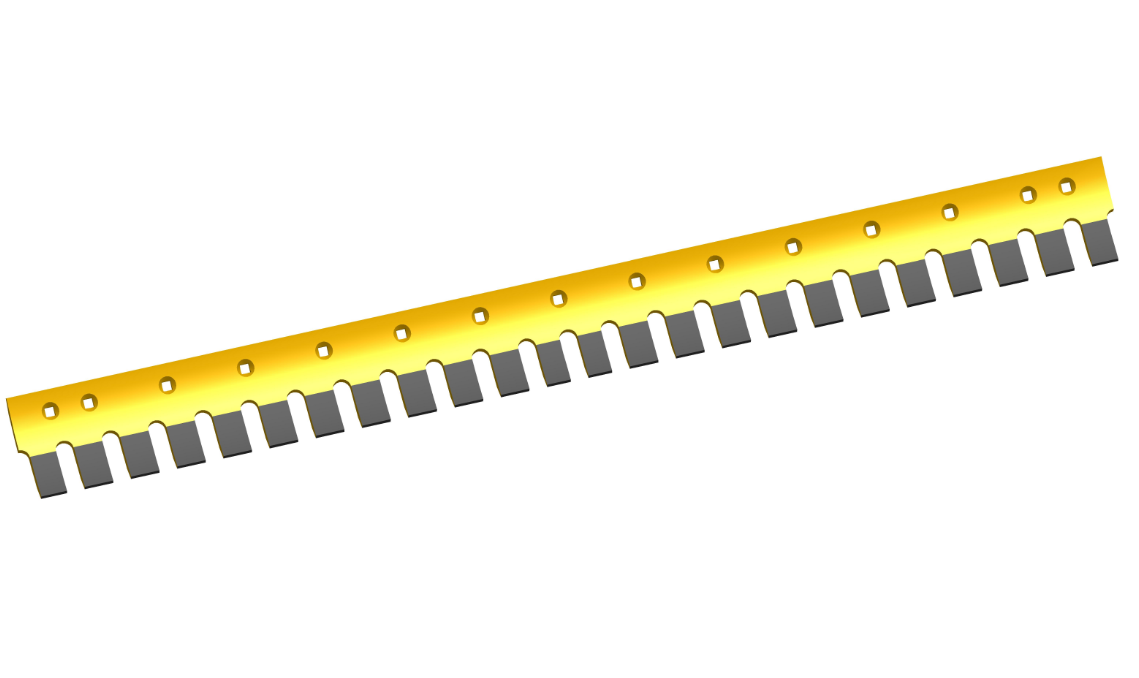

Failure Analysis of Excavator Bucket Teeth: A set of bucket teeth from an open-pit excavator experienced severe wear and early failure during use. This analysis focuses on the failure modes and causes on the surface of the bucket teeth, and proposes improvement measures.

The failure modes of bucket teeth under different working conditions are subject to varying degrees of wear and impact, leading to different levels and forms of failure. Under normal operating conditions, the bucket teeth failed within just 3 days (approximately 36 hours), which is unacceptable both economically and practically. From macroscopic photographs of the failed parts, it is evident that the front working surface of the bucket teeth has obvious groove scratches from plowing, with a small amount of plastic deformation at the tip and no cracks. The front working surface (the contact surface with the ground) is the thinnest, measuring approximately 4mm, while the rear working surface is about 8mm thick.

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province