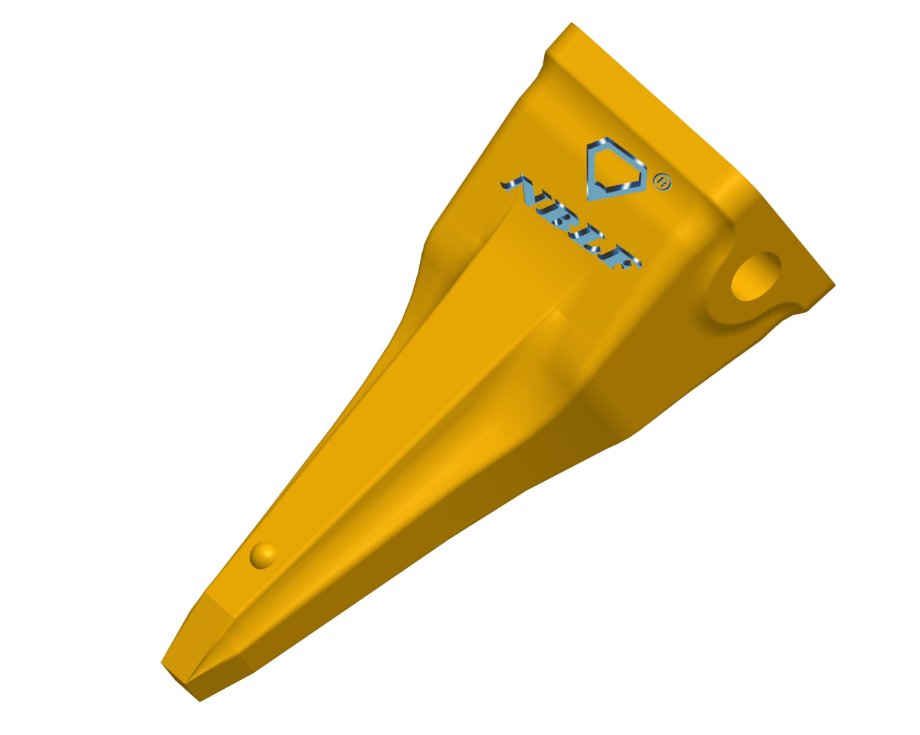

Currently, there are tens of thousands of excavators in service in China. Due to the harsh operating conditions of forging excavator bucket teeth, which involve handling materials such as ore, rock, or soil, the bucket teeth are not only subjected to sliding wear but also endure significant impact loads during excavation operations. This significantly shortens the service life of the bucket teeth, making them the most consumable wearing parts. The low surface hardness of the bucket teeth leads to poor wear resistance and wear. Additionally, some bucket teeth, due to insufficient toughness, undergo brittle fracture under a certain degree of impact, resulting in material waste and economic losses, while also directly affecting production schedules. Therefore, the ideal surface material for excavator bucket teeth, as envisioned by wholesale excavator bucket teeth manufacturers, should possess high hardness and wear resistance, while the base material should exhibit high strength and toughness. However, it is difficult for a single material to achieve all these properties simultaneously.

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province