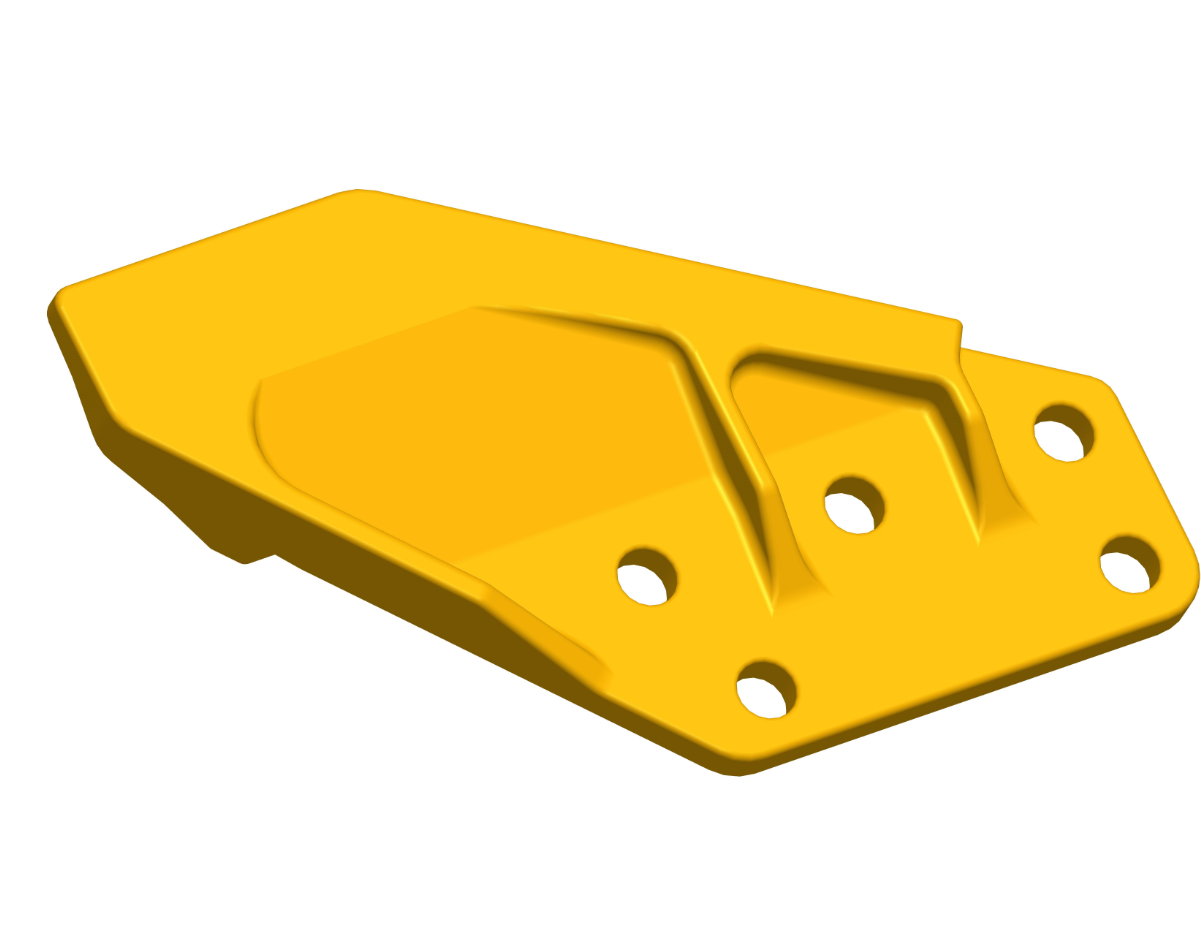

Wear-resistant bucket teeth are vulnerable components of excavators, directly involved in operational tasks. The type, strength, welding seams, plate material, and other parameters of the grab bucket directly determine its service life. Our company employs 2D AutoCAD for structural design and 3D SolidWorks for stress analysis and working condition simulation. Based on the original bucket shape or customer requirements, materials are cut using fully automatic numerical control flame cutting. Subsequently, welding is performed using CO2 shielded welding and submerged arc welding. To enhance durability, we increase plate thickness, welding seam angles, and incorporate wear-resistant chain plates. Zhejiang bucket teeth undergo automatic sandblasting and painting to relieve welding stress, improve overall product quality, and significantly extend product service life.

Phone:13806663265

Domestic call:0574-88474728

0574-88067892

International call:0574-88474588

13806663265

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province