Optimized Information:

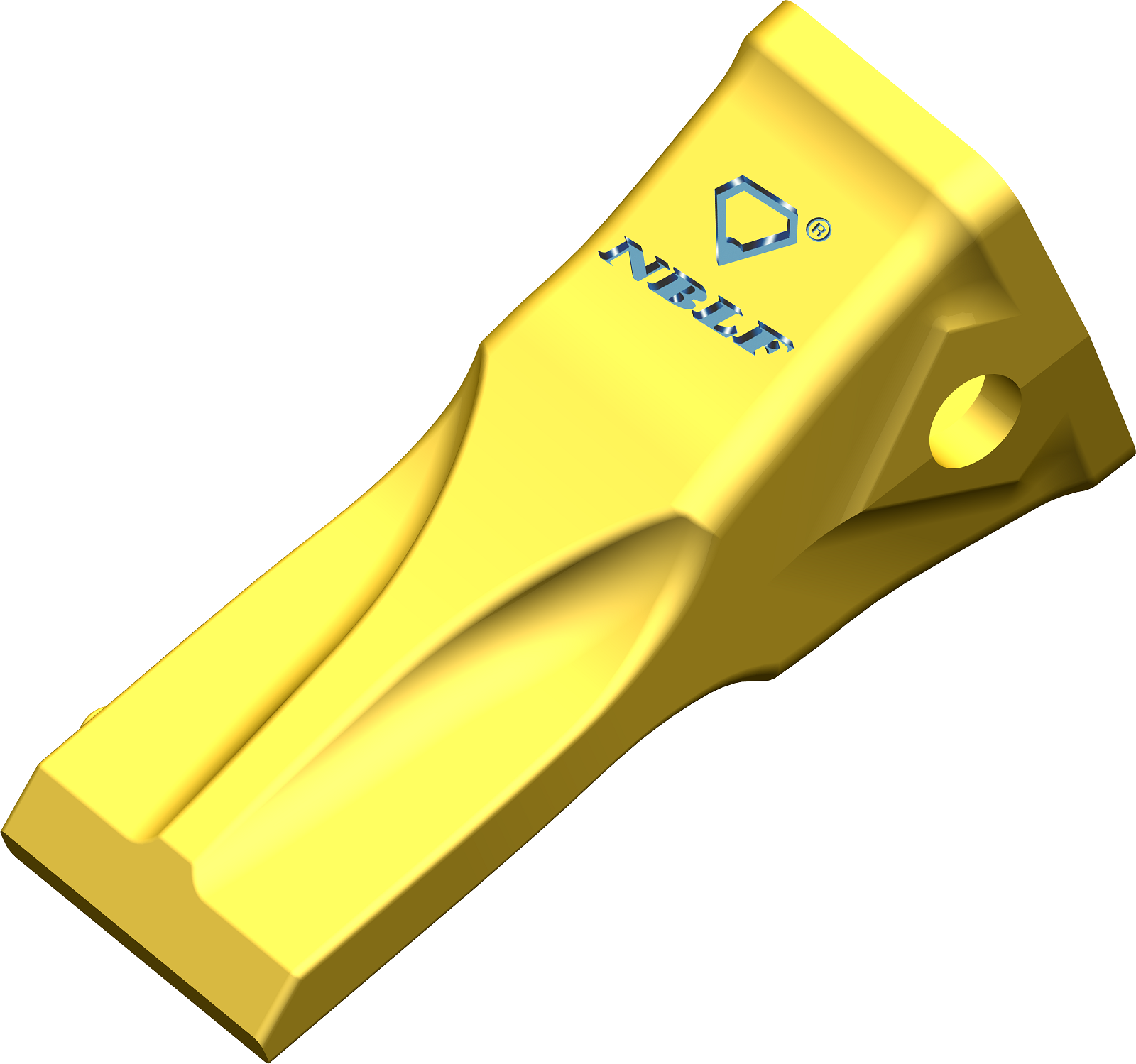

Bucket teeth are important wear parts of excavators, similar to human teeth. The composite bucket teeth, consisting of a tooth holder and a tooth tip, are connected through a pin shaft. Since the wear and failure mainly occur at the tooth tip, only the tooth tip needs to be replaced.

Excavator bucket teeth can be classified into rock teeth (for iron ore, quarry stones, etc.), soil teeth (for digging soil, sand, etc.), and cone teeth (for coal mines). Excavator bucket teeth can also be categorized based on their bases into horizontal pin bucket teeth (primarily for Hitachi excavators), vertical pin bucket teeth (for Komatsu excavators, Caterpillar excavators, Daewoo excavators, Shenggang excavators, etc.), and rotary bucket teeth (V-series bucket teeth).

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province