The excavator bucket resembles a dustpan, featuring a toothed bottom plate and bucket teeth. During operation, the bucket body is thrown onto the excavation surface. The bucket teeth cut into the soil layer through their own weight. Subsequently, the bucket is excavated by pulling it along with a wire rope. After full excavation, the bucket is lifted using a lifting rope. The tipping bucket adjusts the soil unloading point through a turntable to discharge the soil. It is possible to excavate below the soil retaining surface, but the excavation accuracy is poor.

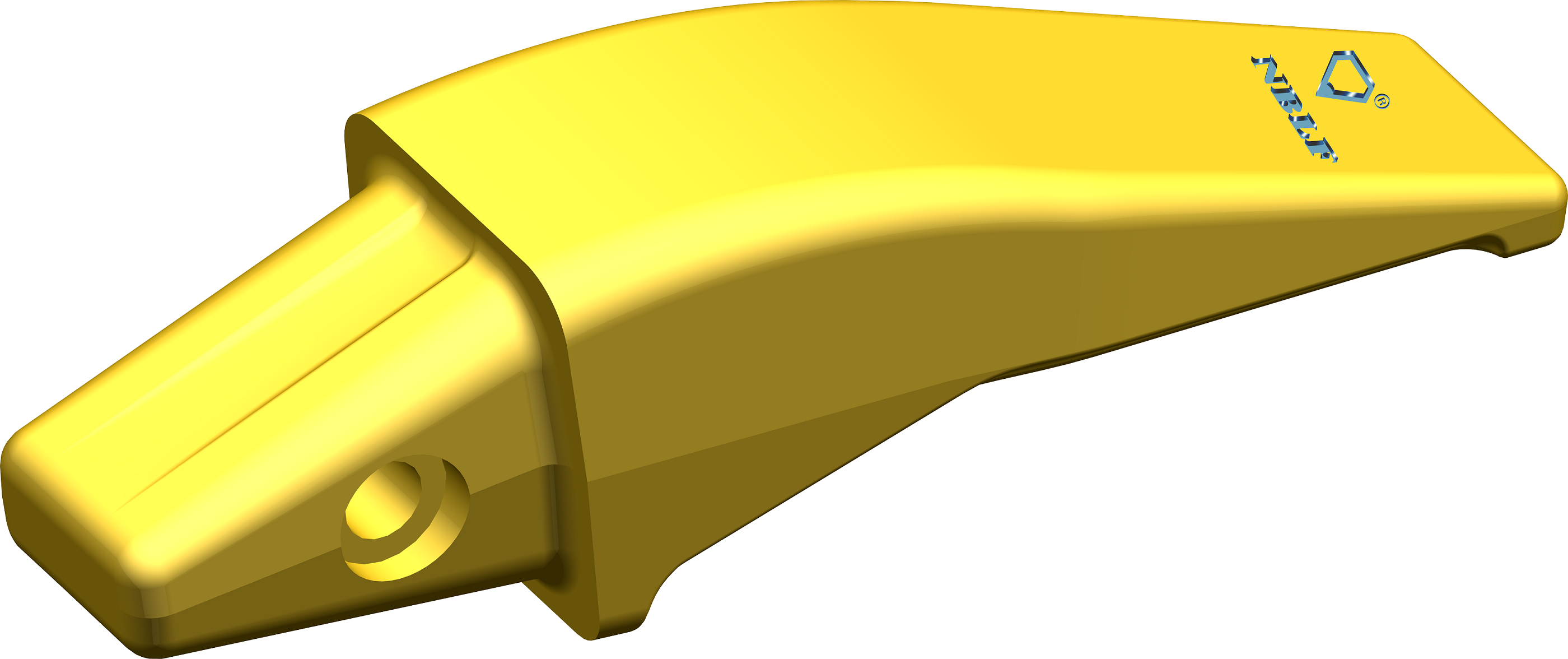

Excavator buckets can be classified into standard, reinforced, and mining types based on their structure and material properties.

Standard buckets are made of Q345B, a domestically produced high-quality high-strength structural steel. The characteristics of standard buckets include a large bucket area, a large heaping surface, a high filling coefficient, saving operating time, and high efficiency. They are suitable for excavating general clay and loading sand, soil, and gravel.

Reinforced buckets are made of high-strength wear-resistant steel materials on the basis of standard buckets, especially for high-stress and vulnerable parts. The toothed bottom plate and vulnerable side edges are made of high-quality high-strength wear-resistant steel NM360, with thicker plates to extend service life. They inherit all the advantages of standard buckets while significantly improving strength and wear resistance. Suitable environments for their use include heavy-duty operations such as excavating hard soil, gravel, and gravel loading.

Phone:0574-88474588

Tel:0574-88474588

Email:Master@nblfcast.com John@nblfcast.com

Add:Hehuaqiao Industrial Zone, Yunlong Town, Yinzhou District, Ningbo City, Zhejiang Province